Standard air handler dimensions are super important when you’re dealing with HVAC systems. Getting the size right is key for efficient cooling and heating, and it also impacts how easy (or hard!) the installation process will be. This guide breaks down everything you need to know about common sizes, installation considerations, energy efficiency, and more, so you can choose the perfect air handler for your space and needs.

We’ll cover everything from typical dimensions for different capacities to troubleshooting common installation problems.

We’ll explore how factors like manufacturer, features, ceiling height, and ductwork placement all play a role in determining the best air handler size. Think of it as your ultimate cheat sheet for navigating the world of air handler dimensions. Let’s dive in!

Common Standard Air Handler Sizes

Air handler dimensions aren’t standardized across the board, leading to some confusion when choosing a unit for your HVAC system. Several factors influence the size and shape of an air handler, resulting in a range of dimensions even within the same cooling capacity. This makes understanding typical dimensions crucial for proper installation and system performance.

While exact dimensions vary significantly by manufacturer and model, we can examine typical size ranges for common air handler capacities. It’s important to always consult the manufacturer’s specifications for the precise dimensions of a specific model before making any purchasing decisions.

Typical Air Handler Dimensions by Capacity

The following table provides a general overview of common air handler dimensions for various cooling capacities (in tons). Remember that these are approximations, and actual dimensions can vary considerably.

| Cooling Capacity (Tons) | Height (inches) | Width (inches) | Depth (inches) |

|---|---|---|---|

| 1.5 | 24-36 | 24-36 | 18-24 |

| 2 | 28-40 | 28-40 | 20-28 |

| 3 | 32-48 | 32-48 | 24-32 |

| 4 | 36-54 | 36-54 | 28-36 |

| 5 | 40-60 | 40-60 | 32-40 |

Factors Influencing Dimensional Variations

Several factors contribute to the range of dimensions observed within each cooling capacity. Understanding these factors helps explain why you won’t find a single, universally applicable size chart.

Manufacturer Differences: Each manufacturer has its own design specifications and manufacturing processes. This results in variations in the overall dimensions of air handlers, even for similar capacities. For instance, one manufacturer might prioritize a compact design, while another might favor a more spacious internal configuration for easier maintenance.

Features and Options: Additional features, such as built-in humidifiers, enhanced filtration systems, or specialized coils, can significantly impact the air handler’s size. A unit with a high-efficiency ECM motor might be slightly larger to accommodate the more sophisticated motor technology. Similarly, models with larger coils for increased cooling capacity will naturally be bigger than those with smaller coils.

Construction Materials: The materials used in the construction of the air handler also play a role. For example, using heavier-gauge metal for increased durability might result in slightly larger dimensions compared to a unit built with thinner materials.

Internal Configuration: The internal layout of components such as the blower motor, coils, and drain pan also influences the overall dimensions. A manufacturer’s design choices regarding the arrangement of these internal components can impact the final size and shape of the unit.

Impact of Dimensions on Installation: Standard Air Handler Dimensions

Choosing the right air handler isn’t just about BTU capacity; the physical dimensions are equally crucial for a smooth installation. A mismatch between the air handler’s size and the available space can lead to significant delays, added costs, and even compromised performance. Understanding the relationship between these factors is key to a successful HVAC project.Air handler dimensions directly dictate the space required for installation.

This includes not only the unit itself but also the necessary clearance around it for maintenance access and proper airflow. Insufficient space can hinder installation, potentially requiring costly modifications to the existing structure or even necessitating the selection of a smaller, less efficient unit. Conversely, selecting an overly small unit might compromise the system’s ability to effectively heat or cool the space.

Ceiling Height and Ductwork Placement Influence on Air Handler Selection

Ceiling height significantly impacts air handler selection. Lower ceilings often necessitate a shallower unit to avoid obstructing headroom. Conversely, higher ceilings allow for greater flexibility in unit selection. The location of existing ductwork is another critical factor. Ideally, the air handler should be positioned to minimize ductwork length and maximize efficiency.

For instance, an attic installation might necessitate a smaller, more compact unit to fit within the limited space and avoid interference with other attic components. A basement installation, on the other hand, might offer more flexibility in unit size and placement.

Step-by-Step Procedure for Determining Appropriate Air Handler Dimensions

A systematic approach ensures the correct air handler size is selected for the available space. This procedure should be followed before any purchase.

- Measure the available space: Accurately measure the height, width, and depth of the intended installation location. Consider all obstructions, including beams, pipes, and electrical wiring.

- Assess ductwork configuration: Determine the location and size of existing ductwork. This will help in selecting an air handler that integrates seamlessly with the existing system.

- Consult manufacturer specifications: Review the dimensions of various air handler models from different manufacturers. Compare these dimensions to the available space measured in step one. Allow for at least 6 inches of clearance on all sides for maintenance.

- Consider access requirements: Ensure sufficient space is available for servicing and maintenance. This usually requires additional clearance beyond the unit’s dimensions.

- Verify compatibility with existing system: Confirm that the selected air handler is compatible with the existing ductwork, blower motor, and other HVAC components.

For example, consider a basement installation where the available space measures 36 inches wide, 48 inches high, and 24 inches deep. After reviewing manufacturer specifications, a model with dimensions of 30 inches wide, 42 inches high, and 20 inches deep would be suitable, leaving adequate clearance for installation and maintenance. In contrast, attempting to install a larger unit might necessitate extensive and costly modifications to the space.

So, you’re trying to figure out standard air handler dimensions for your new build? It’s a total pain, right? Honestly, sometimes I feel like I need a serious escape, maybe something like those awesome Overland adventure trips to clear my head. Anyway, back to those air handlers – remember to check the manufacturer’s specs before you even think about installation; those dimensions can vary wildly.

Air Handler Dimensions and Energy Efficiency

Air handler dimensions play a surprisingly significant role in overall energy efficiency. While factors like the blower motor and insulation are crucial, the physical size of the unit directly influences its operational efficiency and energy consumption. A poorly sized air handler can lead to higher energy bills and reduced system lifespan.The relationship between air handler dimensions and energy efficiency isn’t straightforward; it’s not simply a case of “bigger is better” or “smaller is more efficient.” Optimizing for efficiency involves a careful balance between adequate airflow, minimizing pressure drop, and preventing oversized equipment that cycles on and off too frequently.

Air Handler Size and Airflow

Proper airflow is essential for effective cooling and heating. An air handler that’s too small for the space will struggle to move enough air, leading to inefficient operation and increased energy consumption. The blower motor will have to work harder, using more electricity to overcome the increased resistance. Conversely, an oversized unit may cool or heat the space too quickly, resulting in short, frequent cycles.

This constant starting and stopping puts extra strain on the system’s components and can actually waste more energy in the long run than a slightly undersized unit that runs more consistently. For example, a 3-ton air handler in a space only requiring 2 tons of cooling will cycle on and off frequently, consuming more energy than a properly sized 2-ton unit running continuously.

Impact of Dimensions on Internal Components and Energy Consumption

The dimensions of the air handler directly impact the design and efficiency of its internal components. A larger unit often allows for more efficient coil designs and larger blower motors, which can potentially improve airflow and reduce energy consumption. However, a larger unit also means a larger surface area, leading to potentially greater heat loss or gain depending on the level of insulation.

A smaller, well-insulated unit might perform better in this regard. Consider a scenario where two air handlers, one significantly larger than the other, have the same cooling capacity. The larger unit might use a less powerful blower motor due to better airflow characteristics afforded by its size, but the larger surface area may negate this advantage if it isn’t properly insulated.

Conversely, a smaller, well-insulated unit might use a slightly more powerful motor to compensate for the smaller coil and ductwork, but the reduced heat transfer through the walls could offset this energy cost.

Factors Beyond Size Affecting Energy Efficiency

While dimensions are important, they’re not the only determinant of energy efficiency. The type of blower motor is a major factor. ECM (Electronically Commutated Motor) blowers are significantly more efficient than older PSC (Permanent Split Capacitor) motors, offering substantial energy savings. The quality and thickness of the insulation in the air handler also plays a significant role in minimizing heat transfer, thereby reducing energy loss.

Properly sealed ductwork connected to the air handler also contributes to overall efficiency by preventing air leaks and pressure losses. Finally, the design and efficiency of the evaporator and condenser coils themselves impact how effectively the unit transfers heat, affecting overall energy usage.

Matching Air Handlers to HVAC Systems

Picking the right air handler for your furnace or heat pump is crucial for optimal HVAC system performance. A mismatch can lead to inefficient heating and cooling, higher energy bills, and even premature equipment failure. This guide Artikels the process of selecting a compatible air handler, focusing on interpreting manufacturer specifications.Proper air handler selection ensures your system operates at peak efficiency, providing comfortable temperatures and minimizing energy waste.

Understanding the key specifications and matching them correctly to your furnace or heat pump is paramount. Ignoring these details could result in an underperforming or even damaged system.

Manufacturer Specifications and Compatibility, Standard air handler dimensions

Before you even think about buying, you’ll need to gather some information. This involves carefully reviewing the specifications provided by the manufacturer for both your existing furnace or heat pump and the prospective air handler. Key parameters include airflow capacity (CFM), voltage, amperage, and heating/cooling capacity (BTUs). Pay close attention to any specific compatibility notes or requirements.

- Airflow Capacity (CFM): This is a critical parameter. The air handler’s CFM rating must match the furnace or heat pump’s airflow requirements. A mismatch will result in poor heat transfer and reduced efficiency. For example, if your furnace requires 1200 CFM, the air handler should have a similar rating. A significant difference, either higher or lower, will cause problems.

- Voltage and Amperage: The air handler must be compatible with the electrical supply of your home and the HVAC system. Double-check the voltage (typically 115V or 230V) and amperage requirements to ensure a safe and proper connection. Using an incompatible air handler can lead to electrical issues, potentially causing damage to the equipment or even fire hazards.

- Heating/Cooling Capacity (BTUs): While not as directly related to the air handler’s

-physical* dimensions, the BTU capacity of your furnace or heat pump is indirectly related to the air handler’s size. A larger capacity system will often require a more robust air handler to handle the increased airflow needed to distribute the heat or cool effectively. This should be considered when selecting an appropriately sized unit.For instance, a high-efficiency heat pump with a high BTU rating will need an air handler capable of moving a substantial amount of air to distribute that heat effectively.

- Coil Size and Type: The air handler’s evaporator coil (for cooling) and heating coil (for heating) must be appropriately sized for the furnace or heat pump’s capacity. This information is usually specified in the manufacturer’s documentation. Using an incorrectly sized coil will result in reduced efficiency and may cause the system to work harder than necessary, leading to premature wear and tear.

For example, an undersized coil will struggle to handle the heat load, resulting in poor cooling performance.

Interpreting Manufacturer Data Sheets

Manufacturer data sheets provide essential information for matching air handlers and HVAC systems. These sheets often include tables and diagrams that clearly indicate compatible models. Look for sections detailing airflow requirements, electrical specifications, and coil sizing information. Pay close attention to any compatibility charts or matrices that specifically link air handler models with particular furnace or heat pump models.

For instance, a data sheet might list several air handler models, each with its CFM rating and voltage requirements, along with a table indicating which furnace models they are compatible with.

Variations in Air Handler Design and Dimensions

Air handler dimensions aren’t standardized; they vary significantly based on several factors, including the unit’s configuration, the type of HVAC system it’s part of, and the capacity it needs to handle. Understanding these variations is crucial for proper installation and efficient operation. This section delves into the dimensional differences across various air handler designs and configurations.

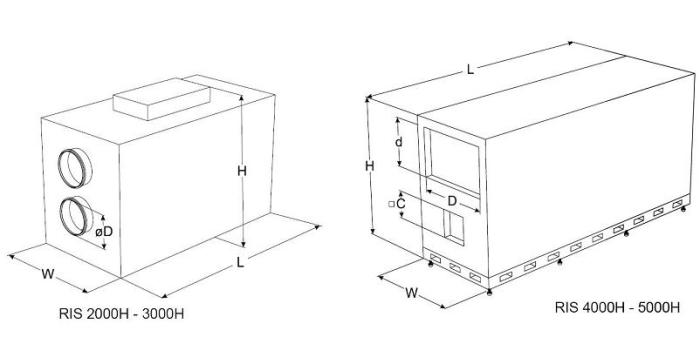

Horizontal vs. Vertical Air Handler Dimensions

Horizontal air handlers, designed to fit within a crawlspace or attic, typically have a wider footprint than their height. Their dimensions are often expressed as length x width x height, with length being the longest dimension. Conversely, vertical air handlers are taller than they are wide and are better suited for closets or utility rooms where space is limited in width and depth but height is available.

A typical horizontal unit might measure 48 inches long, 24 inches wide, and 18 inches high, while a comparable-capacity vertical unit might be 24 inches wide, 24 inches deep, and 36 inches tall. These are just examples; actual dimensions vary greatly depending on the manufacturer and the unit’s capacity.

Impact of Blower Configuration on Dimensions

The type of blower motor significantly impacts an air handler’s size. Single-speed blowers are simpler and generally more compact than variable-speed blowers. Variable-speed blowers, while offering more precise airflow control and energy efficiency, often require more space to accommodate their more complex motor and control systems. A variable-speed blower might add a few inches to the unit’s depth or height compared to a single-speed model with the same airflow capacity.

For example, a single-speed unit might fit snugly into a 24×24 inch space, while a variable-speed model with similar capacity could require a 24×28 inch space due to the larger motor and control components.

Dimensional Comparison of Different Air Handler Types

Gas, electric, and heat pump air handlers all differ in size, primarily due to the inclusion of additional components. Gas air handlers often require more space to accommodate the gas valve, heat exchanger, and other gas-related components. Electric air handlers are generally more compact since they only need to handle electrical components. Heat pump air handlers fall somewhere in between, needing space for both heating and cooling components, but usually smaller than gas units of similar capacity.

A 3-ton gas air handler might be considerably larger than a 3-ton electric air handler, with differences in both depth and height. The presence of additional components like electric heating elements (in heat pump systems) or gas burners also affects the overall dimensions. Precise dimensions are highly manufacturer-specific and depend on the unit’s capacity and features.

Troubleshooting Dimensional Issues During Installation

Air handler installation often hits snags due to unexpected dimensional discrepancies. These problems can range from minor adjustments to major redesigns, significantly impacting project timelines and costs. Understanding common issues and their solutions is crucial for efficient and successful HVAC installations.

Dimensional problems typically arise from inaccurate measurements, unforeseen obstacles within the installation space, or inconsistencies between the air handler specifications and the existing ductwork. These discrepancies can manifest in several ways, leading to difficulties in fitting the unit, connecting ductwork, and ensuring proper airflow. Addressing these issues promptly and effectively is essential for optimal system performance and preventing costly rework.

Common Dimensional Problems and Solutions

Several common dimensional issues arise during air handler installation. For example, insufficient clearance around the unit can prevent proper access for maintenance or servicing. This might necessitate adjustments to the surrounding structure or even a relocation of the air handler. Another frequent problem involves mismatched ductwork sizes, leading to restricted airflow or increased noise levels. This often requires modifications to the existing ductwork, possibly involving the addition of transitions or reducers.

Finally, unexpected obstructions, such as pipes or electrical conduits, within the intended installation space can create significant challenges, sometimes requiring creative solutions to accommodate the air handler without compromising its functionality. Solutions range from simple adjustments to the ductwork’s routing to more complex modifications of the installation location or even the selection of a differently sized air handler.

Addressing Mismatched Ductwork

Mismatched ductwork is a very common problem. It occurs when the existing ductwork doesn’t align with the air handler’s connection points in terms of size, shape, or location. This often necessitates the use of duct adapters or transitions to bridge the gap. For example, if the air handler’s supply outlet is larger than the existing duct, a reducer can be used.

Conversely, if the existing duct is larger, an increaser or a custom-fabricated transition piece may be required. In some cases, rerouting or extending sections of ductwork might be necessary to achieve a proper fit. The key is to ensure a smooth, airtight connection to maintain optimal airflow and prevent energy loss. Failing to do so can result in reduced efficiency and increased noise.

Troubleshooting Flowchart for Dimensional Issues

A systematic approach is essential for efficiently resolving dimensional problems. The following flowchart guides technicians through a logical troubleshooting process:

| Step | Action | Outcome |

|---|---|---|

| 1 | Verify air handler dimensions against installation space measurements. | Sufficient space? Yes/No |

| 2 | If No, assess the possibility of relocating the unit or modifying the installation space. | Relocation/Modification feasible? Yes/No |

| 3 | If Yes, proceed with relocation/modification. If No, consider a different air handler model. | Problem resolved? Yes/No |

| 4 | Check for compatibility between air handler connection points and existing ductwork. | Compatible? Yes/No |

| 5 | If No, determine necessary adjustments (adapters, transitions, rerouting). | Adjustments implemented? Yes/No |

| 6 | If Yes, test for proper airflow and seal any leaks. If No, re-evaluate the ductwork design. | Problem resolved? Yes/No |

| 7 | If problem persists, consult manufacturer specifications and seek expert assistance. | Problem resolved? Yes/No |

Illustrative Examples of Air Handler Dimensions

Understanding the physical dimensions of an air handler is crucial for proper installation and optimal HVAC system performance. Different models cater to various needs, impacting both the space required and the overall efficiency. The following examples illustrate the variety in air handler sizes and how these dimensions affect typical installations.

Air Handler Model A: Compact Unit for Smaller Spaces

This model, ideal for smaller homes or apartments, boasts a compact design without sacrificing performance. Its dimensions are 24 inches in height, 24 inches in width, and 12 inches in depth. The unit has a capacity of 2 tons (24,000 BTUs), suitable for cooling spaces up to approximately 800 square feet. The shallow depth allows for easier installation in tighter spaces, like closets or utility rooms where larger units might be problematic. The compact size reduces the overall footprint, which is beneficial in homes with limited floor space.

Air Handler Model B: Mid-Size Unit for Average Homes

This mid-range model represents a balance between size and capacity, making it suitable for many average-sized homes. Its dimensions are 36 inches in height, 30 inches in width, and 18 inches in depth. With a capacity of 3.5 tons (42,000 BTUs), it can comfortably cool spaces up to approximately 1,400 square feet. This model’s larger capacity makes it suitable for larger living spaces or homes with higher cooling demands. The increased depth requires more space during installation, but it offers enhanced cooling performance. The increased height might require adjustments to ceiling heights or ductwork configurations in some cases.

Air Handler Model C: High-Capacity Unit for Larger Homes

Designed for larger homes or those with significant cooling needs, this high-capacity model is considerably larger. Its dimensions are 48 inches in height, 36 inches in width, and 24 inches in depth. It boasts a 5-ton (60,000 BTUs) capacity, capable of cooling areas up to approximately 2,000 square feet. The substantial size requires ample space for installation, likely necessitating dedicated mechanical rooms or larger closets. Proper ductwork design is critical for efficient airflow with this unit. The larger capacity also often means higher energy consumption, requiring careful consideration of energy efficiency ratings and potential impact on utility bills.

So, there you have it – a comprehensive look at standard air handler dimensions! From understanding the various sizes and their impact on installation to optimizing energy efficiency and troubleshooting potential issues, we’ve covered the essentials. Remember, proper sizing is crucial for a smoothly running HVAC system and a comfortable home. Armed with this knowledge, you can confidently tackle your next HVAC project.

Happy cooling (and heating!)

Questions and Answers

What’s the difference between a horizontal and vertical air handler?

Horizontal air handlers are designed to be installed horizontally, typically in attics or crawl spaces, while vertical air handlers are designed for vertical installation, often in closets or utility rooms. This impacts the overall dimensions and how they fit into your space.

How often should I replace my air handler?

The lifespan of an air handler varies, but typically ranges from 15 to 20 years. Regular maintenance can extend its life, but eventual replacement is inevitable due to wear and tear.

Can I install an air handler myself?

While some DIYers attempt it, installing an air handler is generally recommended for HVAC professionals. Improper installation can lead to safety hazards and inefficiency.

What are the typical costs associated with air handler replacement?

The cost varies widely based on the size, features, and labor costs in your area. Expect to spend anywhere from a few hundred to several thousand dollars.